A recent study published in Gels, as well as the U.S. National Library of Medicine, has introduced a groundbreaking approach to CBD gummy production using 3D printing.

Conducted by researchers at Florida A&M University, the study highlights the potential of 3D-printed CBD gummies as a customized, patient-friendly alternative for pain management, particularly in the geriatric population.

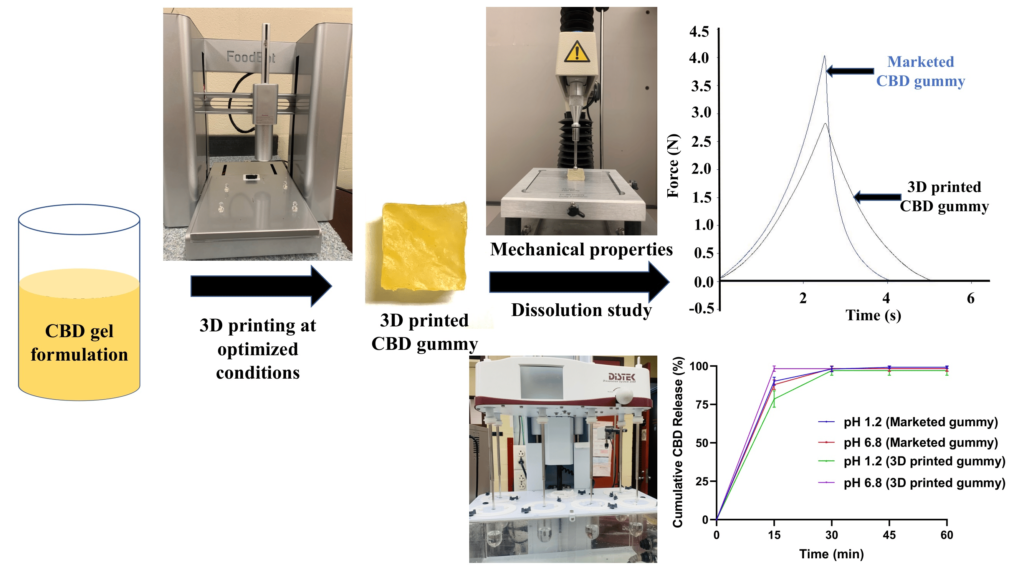

Oropharyngeal dysphagia (difficulty swallowing) and chronic pain are common issues among older adults, often making traditional pill-based medications less effective or harder to consume. To address this, the researchers developed a gelatin-based CBD gummy formulation and tested its suitability for 3D printing using a syringe-based extrusion printer.

Their findings showed that the 3D-printed gummies had higher elasticity compared to conventional molded CBD gummies while maintaining similar toughness. The gummies were printed at an optimized temperature of 38°C, with a filament diameter of 26 mm and a flow rate of 110%. Importantly, CBD content remained consistent, with 3D-printed gummies containing 98.14% ± 1.56% CBD, closely matching the 97.97% ± 2.14% found in commercial alternatives.

In vitro dissolution tests further confirmed that both 3D-printed and traditional gummies released 100% of their CBD content within 30 minutes in both acidic (pH 1.2) and neutral (pH 6.8) conditions. This suggests that 3D-printed CBD gummies can deliver rapid and effective CBD absorption, making them a viable option for patients who require precise and customizable dosing.

“Overall, 3D printing enables customizable CBD gummies with optimized release and offer a personalized and patient-friendly alternative to traditional oral forms for geriatric care”, concludes the study.