By Herb Pyrolysis

Seasoned consumers have long known that the ensemble effect from smoking cannabis/hemp flower buds is unbeatable, but health concerns have driven some to try dry herb vaporizers as an alternative.

While the best of the commercially available dry herb vaporizers (e.g., Volcano, FireFly, DynaVap, etc.) have seen considerable success and do perform, they all produce excessive waste, in that the used brown residue from these devices includes substantial cannabinoids. The answer to this problem is pyrolysis, which savvy consumers will quickly discover lies in the sweet spot between vaporization and combustion. Pyrolysis means that all of the compounds worth consuming are gasified at extreme temperatures in an oxygen starved mini oven. The gasified compounds are moved out of the mini oven, condensed into a cloud, and carried to the user’s lungs. The residue from pyrolysis is black biochar, which is neither ash nor brown matter. The ensemble effect possible only through pyrolysis may be superior to all other methods of consuming dried herb. There is now a patent pending personal pyrolysizer that delivers a true breakthrough in cannabis/hemp consumption technology.

While the best of the commercially available dry herb vaporizers (e.g., Volcano, FireFly, DynaVap, etc.) have seen considerable success and do perform, they all produce excessive waste, in that the used brown residue from these devices includes substantial cannabinoids. The answer to this problem is pyrolysis, which savvy consumers will quickly discover lies in the sweet spot between vaporization and combustion. Pyrolysis means that all of the compounds worth consuming are gasified at extreme temperatures in an oxygen starved mini oven. The gasified compounds are moved out of the mini oven, condensed into a cloud, and carried to the user’s lungs. The residue from pyrolysis is black biochar, which is neither ash nor brown matter. The ensemble effect possible only through pyrolysis may be superior to all other methods of consuming dried herb. There is now a patent pending personal pyrolysizer that delivers a true breakthrough in cannabis/hemp consumption technology.

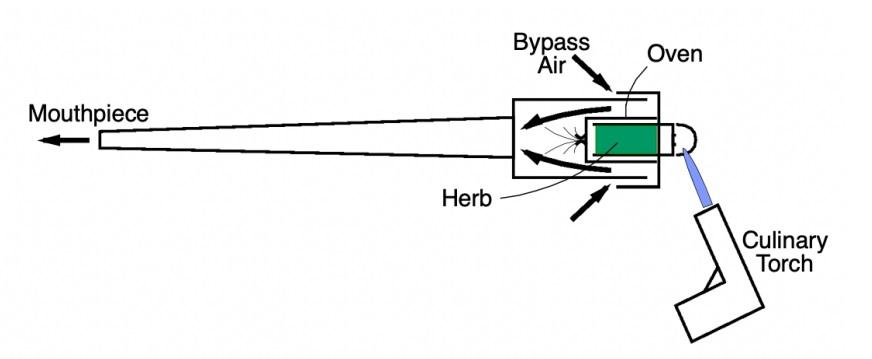

Pyrolysis has all the advantages of combustion, but without the harmful smoke particulates and burnt carcinogens. Pyrolysis occurs a high temperatures ( >450F) where the dried herb would normally combust in air, but the herb cannot burn without oxygen. A mini oven containing the ground dried herb is starved of oxygen by 2 displacing air out of the mini oven with water vapor (usually 10-12% of dried herb mass) and carbon dioxide, which is produced as rising temperatures decarboxylate cannabinoids in the dried herb. With inadequate oxygen, no combustion occurs, while higher temperatures cause essential plant oils to vaporize quickly and completely. When a user draws on a mouthpiece, fresh air bypasses the mini oven and carries the gasified cannabinoids and hundreds of other compounds out of the mini oven toward the mouthpiece. The bypass air quickly cools the gasified products from the mini oven into a familiar aerosol cloud that the user pulls into their lungs in a conventional manner. Pyrolysis has the potential to produce a superior, and previously unknown, cannabis/hemp experience.

There is little question that currently available dry herb vaporizers can produce tasty clouds of cannabinoids and terpenes, but a substantial portion of these valuable compounds never vaporize and become part of the brown matter waste from these devices. Limited heat transfer is the reason that less than all of the essential oil is vaporized. It takes a tremendous amount of energy to transform a liquid into a gas, and heated air is a poor means of transferring heat to the essential oil in the dried herb. Commercial vaporizers also must operate at lower temperatures to avoid combustion, thus undermining the synergism associated with the ensemble effect. Pyrolysis, on the other hand, relies upon conductive and radiant heat transfer to efficiently vaporize a broader band of compounds present in the herb essential oil. Pyrolysis can inherently do everything and more than the best dry herb vaporizers, and do so without waste. 3 Pyrolysis can also inherently equal the performance of combustion, but do so without harmful smoke. The proof is visible when one compares the carbon rich black biochar residue from pyrolysis to gray ash from combustion and the familiar browned herb residue from the best vaporizers.

Pyrolysis has long been known as one way to extract biofuel precursors from plant matter biomass on an industrial scale. Until now, no one has taught how to achieve effective pyrolysis at the relatively tiny scale associated with processing a personal quantity (e.g., 0.5gm) of dried herb. Efficient, tasty and complete extraction and consumption of essential oil from high quality dried herb is a standard only achievable through pyrolysis. Controlling the personal pyrolysizer introduced above may be accomplished by controlling the bypass air flow rate via a suction rate at the mouthpiece, and independently control a rate of heat transfer with appropriate positioning of a torch flame. More uniform heat transfer is maintained in the mini oven via a copper heat exchanger that isolates the dried herb from air and an extremely hot flame. The pyrolysation process may be observed through a window, providing useful feedback to the user to adjust one or both of the bypass air flow rate via suction intensity at the mouthpiece, and heating intensity with the torch responsive to an aerosol cloud density visible through the window. Experience suggests that different users prefer pyrolysis at different temperatures and rates. The personal pyrolysizer permits a user to customize their own experience according to their own tastes and preferences. When the aerosol cloud density wanes in the window, the user recognizes that the process is complete, and the herb sample is exhausted. After 4 cooling, biochar residue may be removed from the mini oven, which may then be reloaded with dry herb for another pyrolysis cycle.

Humans have long exploited pyrolysis in other ways. For instance, pyrolysis has been used to turn wood into charcoal since ancient times, often by using a smoldering fire in a closed pit packed with wood, as depicted above. As the wood heats, compounds turn to gases and are vented off. After a prolonged period, the gasified compounds are removed from the wood leaving behind valuable carbon rich black charcoal for heating and cooking. Charcoal is the same as biochar. Thus, humans have previous experience with pyrolysis, but with the new herb pyrolysis technology, the valuable thing is to capture and consume the gasified compounds, leaving the biochar as waste. In comparison, wood is to dried herb as charcoal is to biochar. Pyrolysis is a process that takes time, and the duration is often proportional to the mass being pyrolysized. In this way, herb pyrolysis is akin to cooking. Both can be done fast and hot or warm and slow, with drastically different results. The best heat transfer profile for herb pyrolysis remains unknown, but is likely a matter of taste with some preferring a multiple suction cycle lower temperature experience, while others prefer to consume the herb compounds fast and hot.