A study published by Industrial Crops and Products reveals that fine-tuning indoor lighting can dramatically boost CBD yield, growth, and energy efficiency in cannabis cultivation.

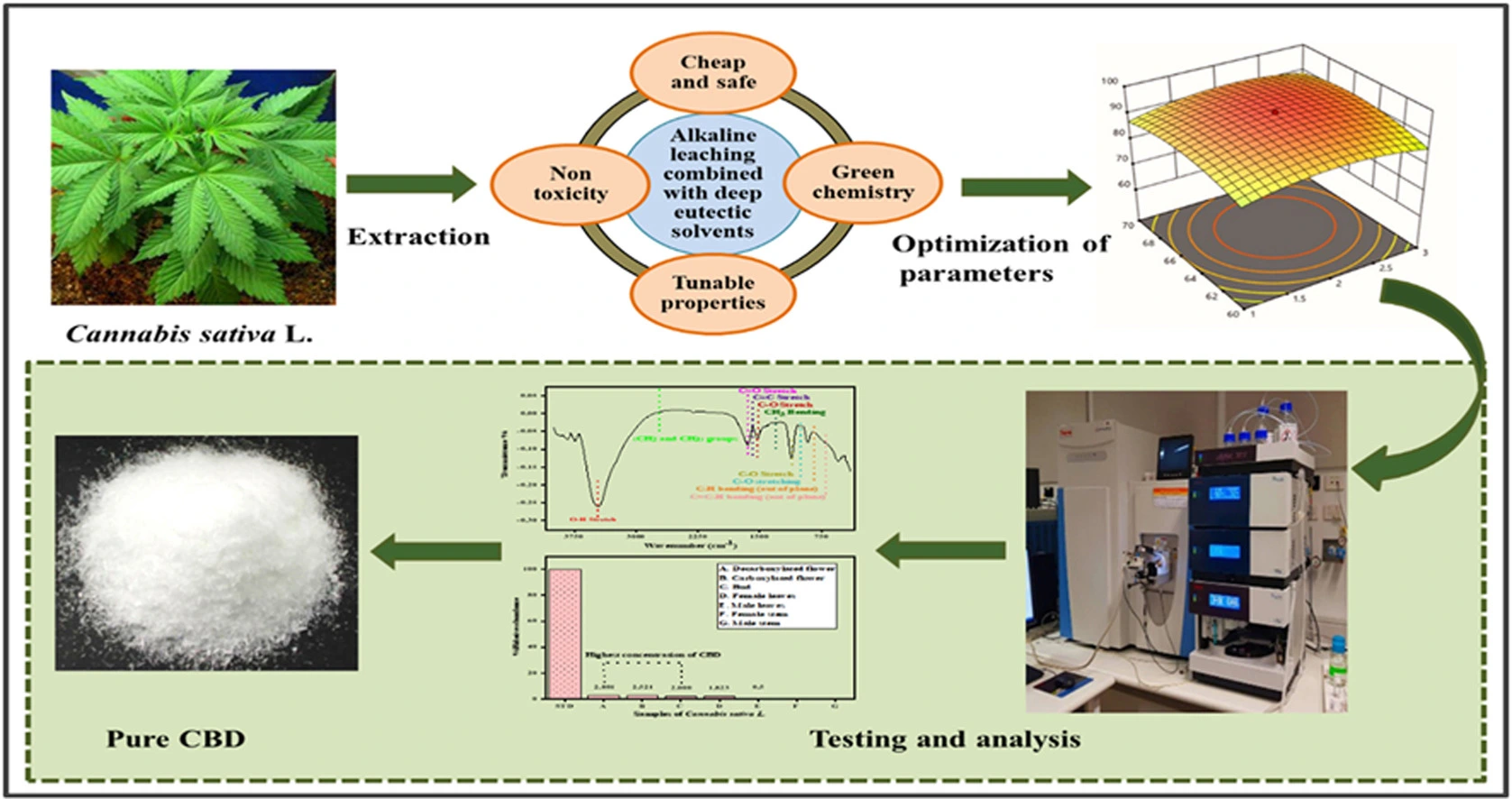

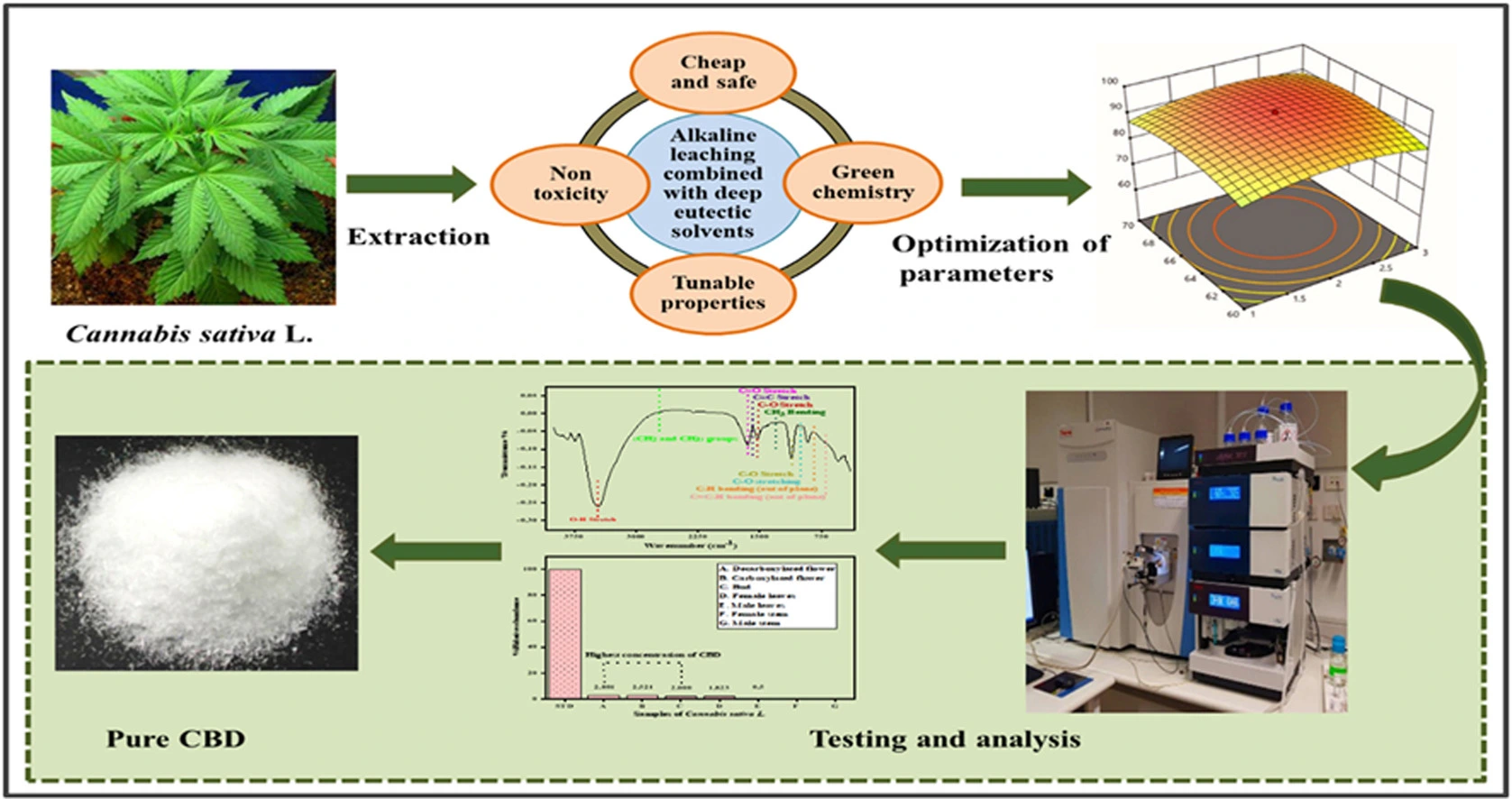

Researchers from East China University of Science and Technology developed a technique that combines deep eutectic solvents (DES)—a mix of ethanol and lactic acid in a 2:1 ratio—with alkaline leaching using sodium hydroxide (NaOH). The process was fine-tuned using response surface methodology to identify optimal pH levels, leaching duration, and extraction temperatures.

The resulting method achieved an 83.48% CBD purity rate—32% higher than traditional ethanol extraction—and a yield of 14.8 mg of CBD per gram of raw material. The team used QE-LC/MS and FTIR to confirm the composition and structural integrity of the extracted CBD, while degradation kinetics were studied to determine optimal storage conditions at -4°C and 20°C.

Unlike toxic organic solvents, DES are made from naturally derived, biodegradable ingredients and are non-flammable, making them safer for industrial-scale extraction. The alkaline environment breaks down plant cell walls, increasing cannabinoid availability, while the dual polarity of DES improves solubility for both hydrophilic and hydrophobic compounds.

The study demonstrates that combining DES with alkaline leaching offers a scalable, environmentally sustainable solution for extracting high-purity CBD—one that may soon become standard in industrial applications.

The study’s full abstract can be found below:

Abstract

Cannabidiol (CBD), a non-psychoactive phytocannabinoid, has garnered attention owing to its paramount medicinal potential and leisure purposes. However, to meet the growing practical demand, obtaining high-purity CBD without toxic organic solvents and suitability for large-scale processing of raw materials with simple and low-cost extraction processes has become a major practical issue. This study proposes an innovative and viable technique for extracting CBD by conjugating deep eutectic solvents (DES) (ethanol and lactic acid 2:1) with alkaline leaching (NaOH). All process parameters, including leaching duration (time), pH, and extraction temperature, were optimized meticulously using response surface methodology (RSM). The CBD-rich part of the plant was identified by QE-LC/MS analysis. The outcomes were validated by repeated experiments with the highest yield of 14.8 mg/g. The adopted method produced 83.48% pure CBD, which was 32% more effective than ethanol leaching, as proven by HPLC analysis. Fourier transform infrared spectroscopy (FTIR) provided insight into the composition of the extracted CBD, confirming its integrity and chemical structure. Degradation kinetic analysis provided insight about the storage temperatures. The results indicated that the extracting technique was simply reliable and environmentally safe, proven by environmental impact assessment indicators, and can be utilized on an industrial scale for economically extracting bioactive compounds from various plant sources.

Thank you for reading The Marijuana Herald! For more news articles, click here.